Safe Explosion Hazard Test

Safe Explosion Hazard TestThe safe is locked in a preheated furnace set to 2000°F. This temp is maintained a specific length of time (30 minutes for a 1-hr fire rating is an example)

If it doesn't explode, the safe then cools inside the closed furnace. Once cooled (this can take days), it's opened and examined for usability, as above.

Safe’s Fire Impact Test (Manufacturer's Option)

For the safe's impact test, the safe is placed in a furnace, following the same time and temperatures used in the Fire Endurance Test.

At the end of the required time in the furnace, the oven is turned off, and within 2 minutes from the fire being turned off, the safe is dropped 30 feet onto a pile of loose bricks over concrete.

It's brutal. But if your safe was on the third story, and the floor burnt through, you'd want to know if you have any protection. But wait … there's more ...

When the safe has cooled sufficiently to handle, it's then turned upside down, and again goes through the testing procedure. Then it's allowed to cool, inside the closed furnace. Then it's inspected for usability. Again.

Many of the fire safes from one of our favorite manufacturer, Hollon, (see Are Hollon Safes Good Safes) have survived this test.

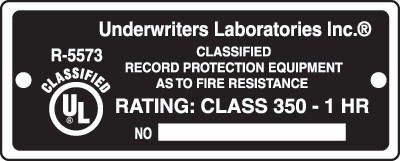

In the UL safe fire rating system, the safes must be tested again after one year of manufacturing to maintain their rating, and the rating is good for comparably built safes down to 50% volume smaller or up to 50% volume larger.

Other Safe Fire Rating Systems

Other Safe Fire Rating SystemsTesting to achieve a Safe's UL fire rating is no small affair, and it can cost more than $60,000 (plus the costs of the safes scarified to the testing ovens). In many cases safe manufacturers just can't pony up that kind of money for each safe they have to test, especially for new manufacturers with limited funding.

Because of this, safe manufacturers may hire an independent company other than UL to perform their safe fire ratings. The three most common alternative fire certification agencies are the KIS, JIS and ETL certifications.

KIS Fire Rating

The KIS fire rating is the Korea Industrial Standards rating defined by fire test

KSG-4500. The KIS KSG-4500 is a slightly different standards that tests safes at external temperatures of 1700° F to 1850° F while maintaining an interior temperature below 350° F.

JIS Fire RatingThe JIS Safe Fire Rating is a safe fire certification out of Japan under specification S 1037-12. The S 1037-12 test uses external temperatures from 1700° F to 1850° F . This fire rating also typically includes a drop test.

ETL Fire Rating

ETL Fire RatingThe ETL-Intertek laboratories is a safe fire rating facility that is being used frequently in the US. They do all of their fire rating tests at 1200 degrees. They've been in business for over 100 years. Safe companies, such as American Security Safes, use this fire test certification.

Whether it’s UL fire rating, KIS Fire Rating, ETL or the JIS fire rating, standardized testing is the best way to ensure the safe will succeed in its fire rating.

Manufacturer Fire Rated ClaimsMany manufacturers will do their own testing and give their own rating. Be wary of these!

This is an internal company test with no oversight, and may in fact only be a guess or they conduct the test under the most favorable conditions (like slowly over 40 minutes, which doesn't really give you an accurate assessment). They may also reduce the external temperature to as low as 1200°F.

Check out our article on Getting the Best Fire Rated Safe – many safes that have had their own testing, don’t achieve even close to the time they are “fire rated” for.

While an internal fire rated safe may be perfectly capable, do your research and try to determine how the fire rated tests were performed.